Blocking and bracing of cargo in shipping containers

One-fourth of all cargo loss and damage that occur during shipments arise as a result of poorly fastened cargo boxes and objects carried inside containers, studies have revealed. This loss is largely preventable with care, attention and the application of guidelines stipulated for securing cargo inside the containers.

Let us understand the meaning of “blocking & bracing” and learn how they play a crucial role in keeping cargo safe and secure from damage during transit across the seas, trucks and railroads.

Goods positioned inside containers are prone to sliding caused by unintentional movements of containers during sea voyages and intermodal transportation. The chief purpose behind blocking & bracing is to prevent the goods inside containers from involuntary motions and guarantee their safety till they are offloaded at the final destination.

“Blocking”, as the term suggests, is specifically intended to prevent cargo from moving side-to-side and additionally, front-and-back. “Bracing” is a method of preventing the cargo from moving up-and-down. Both, “blocking” and “bracing” are interdependent and complement each other’s function because without bracing a load may well jump over the blocks, and without blocking, the bracers themselves will not be able to endure the forces acting upon them arising from lateral movement of the cargo.

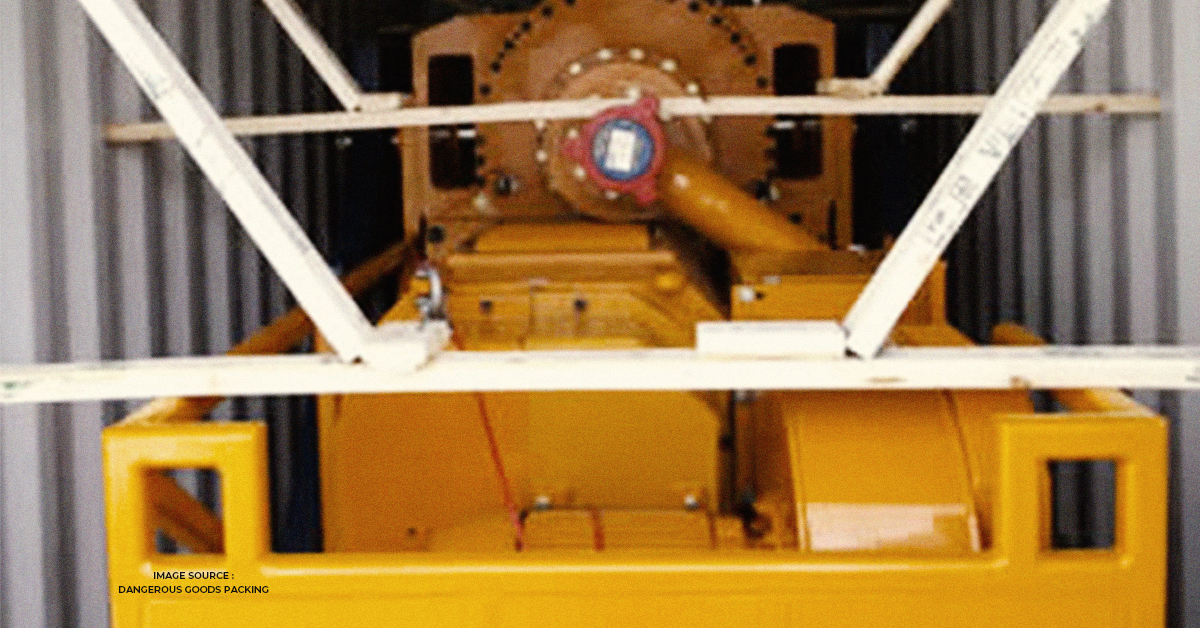

Blocking & bracing involves employing wooden and metal beams to secure the cargo positioned inside the containers. It is interesting to realize that the heavier objects inside containers require particularly strong blocking & bracing. This is because when a shipping container is in motion, the momentum of objects placed inside is proportional to their weight. During intermodal transportation that involves roads and rails, objects inside the containers are prone to excessive rolling, side-to-side movements, pitching front-to-back, sudden impacts, irregular motions known as “yawing” and vibrations. Appropriately blocked and braced objects have the capacity to withstand all these movements and shocks, thus keeping the cargo safe from damage.

An important fact one must be mindful of is that blocking & bracing in itself is not the final answer in preventing accidental cargo movements inside the containers. But more significantly, it is taking the care to firmly secure the blocks to the container body that contributes to the stability of the cargo. Force applied on an object gets transferred more powerfully to blocks placed underneath. Therefore the blocks themselves must be firmly secured to the floor of the container.

Blocking & bracing objects with wheels

Shipping cargo with wheels, like automobiles, for instance, requires special attention. The first step entails preventing the wheels from rotating involuntarily by using straps, blocks, bars or customized transportation brakes. The next step involves securing the cargo itself to the container with bars to prevent vertical and horizontal movements.

Distributing weight evenly across the container floor contributes to stability and prevents the cargo from moving front-to-back and side-to-side. To stabilize and secure loads, one must take advantage of dunnage solutions like foam & plastic partitions and fillers that are designed specifically for intermodal transportation. Cushioning and shock-absorbing accessories like airbags, honeycomb fillers, void-space fillers, drop-down fillers, plywood and particle board dividers come in handy and must be employed generously wherever required.

Although placing metal and wooden beams geometrically to inhibit the movement of cargo does help, some containers come equipped with metal hooks on the insides, near the end corners. They can be used to attached ratchet straps to prevent the cargo from moving, and even serve as additional reinforcements for the blocking & bracing systems which can be drilled into the wooden floor of the container. “Netting” is yet another method employed to offer additional security to the cargo.

For the reasons mentioned above, obeying blocking & bracing procedures is an important necessity in intermodal shipments. It eliminates the risk of damage to general cargo and specialized equipment, besides eliminating the chances of accidents causing injury and death. It saves preventable expenditures involved in repairs, delays, compensation and insurance claims.

- Log in to post comments