The Hidden Costs of Poor Container Design

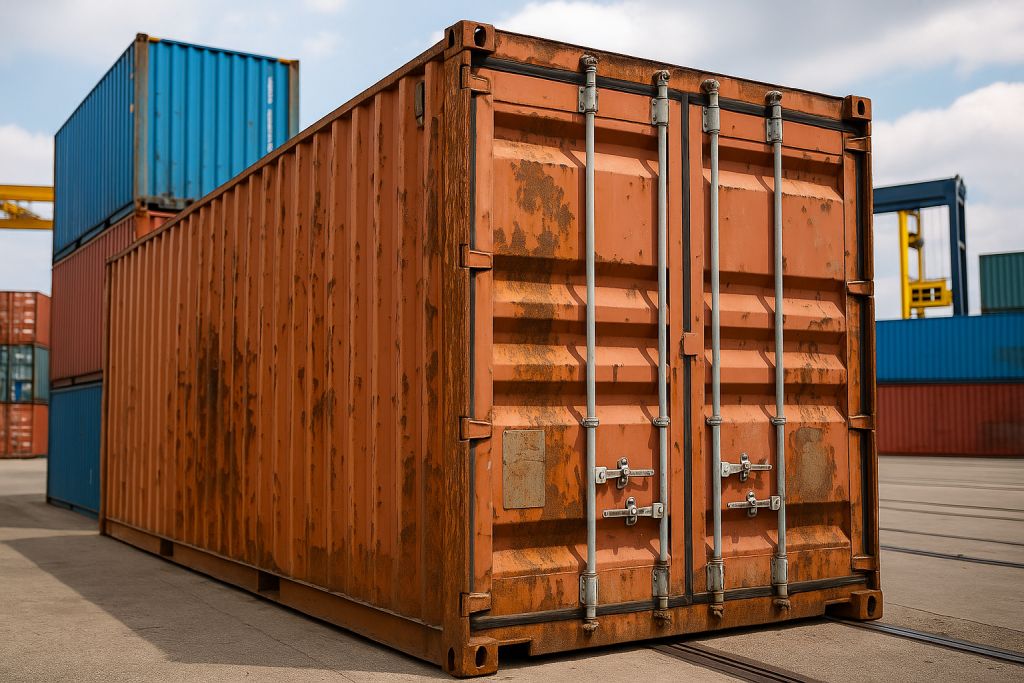

At first glance, a shipping container might seem like a standard box — rigid, uniform, and straightforward. However, a poorly designed container can cause a ripple effect of issues throughout the container supply chain, impacting everything from cargo safety to cost efficiency.

At VS&B Containers Group, with more than two decades of expertise — soon approaching 30 years in shipping container leasing, buying, and selling, we understand the nuances of container design and how critical it is to ensure the safe and efficient movement of goods.

Cargo Safety at Risk

One of the most immediate consequences of poor container design is compromised cargo safety. Subpar materials, faulty locking mechanisms, or inadequate ventilation can expose cargo—especially temperature-sensitive or hazardous goods—to damage. This is particularly crucial when transporting specialized cargo in reefer containers for lease, ISO tank containers, or even GP containers.

Damaged goods not only incur replacement costs but also affect your credibility with customers. Investing in well-designed, standardized international trade containers reduces the likelihood of in-transit damage and ensures compliance with global safety standards.

Operational Inefficiencies Add Up

Containers that aren’t optimized for TEU capacity and efficiency can lead to space wastage during intermodal transport or containerized rail freight. For example, non-standard dimensions or poor weight distribution can result in underutilized space in vessels, railcars, or trucks. This inefficiency adds hidden costs through higher freight charges and lower cargo throughput.

Moreover, poorly maintained or outdated containers often cause delays during port handling or loading operations. Delays translate to demurrage charges, additional warehousing, and missed delivery timelines — all of which affect your bottom line.

Increased Maintenance and Shorter Lifespan

Durability is one of the cornerstones of good container design. Low-quality materials and poor construction techniques increase the frequency of repairs and reduce the container’s lifespan. At VS&B, we place emphasis on sourcing containers built for longevity and shipping container durability, helping our customers lower their container fleet management costs over time.

Safety, Compliance, and Liability Concerns

Containers used for hazardous cargo container shipping or carrying goods across international borders must meet rigorous regulatory requirements. A container design that fails to align with these standards exposes the shipper or operator to fines, shipment rejections, or even legal liability.

Freight Cost Optimization through Better Design

A well-designed container helps with freight cost optimization in numerous ways — from efficient loading to fewer damages and reduced turn-around time. When choosing containers for leasing or purchase, it’s crucial to consider not only the upfront cost but also long-term design benefits that reduce operating expenses.

Choose the Right Partner

As a trusted name in the container leasing and trading business, VS&B Containers offers a wide range of standard and custom container modifications designed to enhance usability, safety, and cost-efficiency. Whether you’re looking for domestic container transport solutions or need containers for complex multimodal logistics, our team ensures every container meets global quality standards.

VS&B Containers group offers both standard and custom-made containers, delivered directly from the factory to your desired location. With a fleet of over 30,000 containers made available across Europe and Asia, the company helps customers get containers effortlessly from anywhere in the world. If you have unique needs in terms of affordability, adaptability, and potential return on investment, please drop an email to traders@vsnb.com, and the VS&B team will contact you to discuss further.

- Log in to post comments