Container Handle Dynamics: An Analysis of 4-Handle vs. 3-Handle Containers

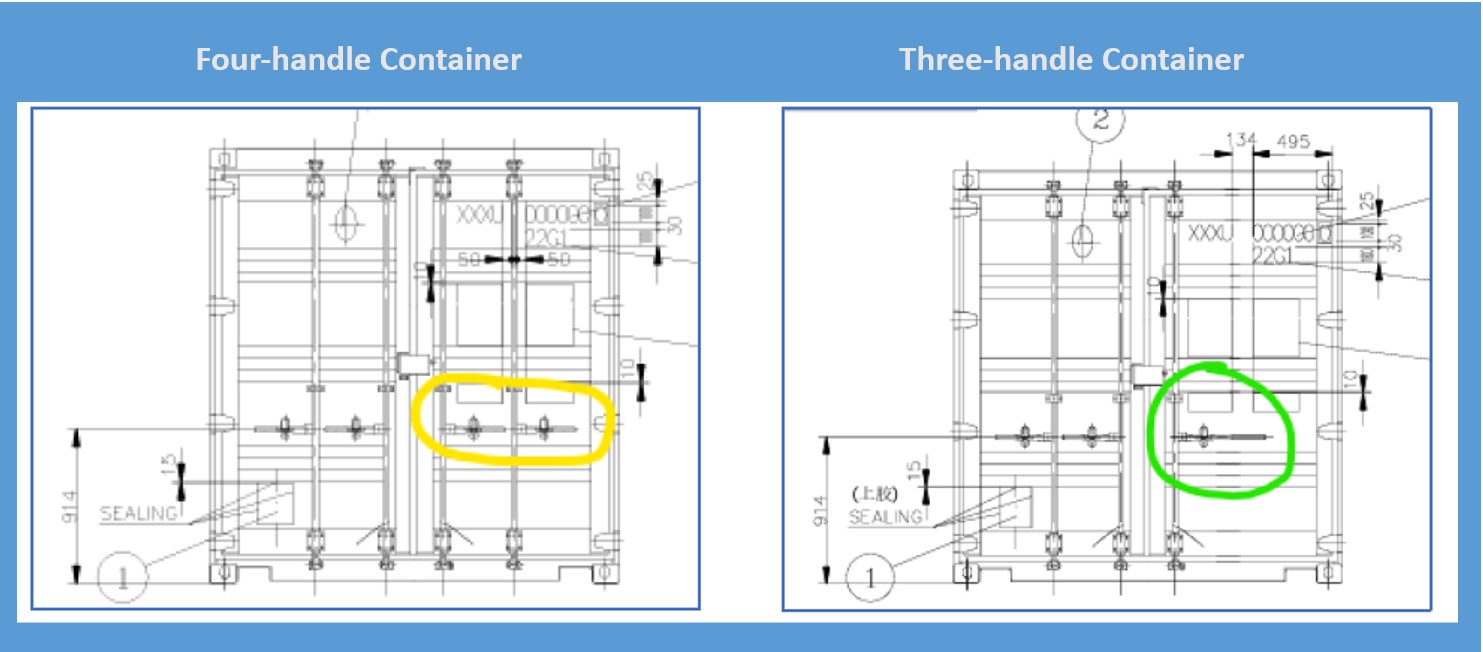

Shipping containers, the workhorses of global trade, come in various configurations, and one such differentiator is the number of locking bars and handles on their doors. In the container world, a debate centres around four-handle and three-handle units, each with its own set of advantages and use cases.

The Debate of Handles: Structural Considerations

From a structural perspective, the four-handle container is known for its sturdiness. The additional handle not only contributes to the rigidity of the container but also enhances its ability to withstand the pressure exerted by other heavy units when stacked.

Operational Benefits of Four-Handle Containers

The four-handle container offers more than just structural robustness. Its added handle significantly contributes to operational benefits. The sturdier build makes these containers suitable for transporting heavier loads and items requiring extra structural support like liquids in flexibags. When used in shipping and logistics, the fourth handle can add to the expected life span of the container. In addition, the fourth handle offers another option on the right door, which needs to be opened before the left door, for a seal.

Operational Benefits of Three-Handle Containers

Let's not dismiss the three-handle container too quickly. These units have operational benefits that make them valuable in certain scenarios. Their design, particularly the longer handle on the right door, makes them easier to open and close. This can be a significant advantage in situations where more frequent access to the cargo is crucial, such as static storage.

Cargo Compatibility

Cargo type plays a pivotal role in determining the suitability of container handles. The sturdiness of four-handle containers makes them ideal for transporting heavier loads and items that require extra structural support. On the other hand, three-handle containers are not suitable for carrying liquids flexibags or bulk in bulkbags, as the pressure on the door is too high for the 3 handles to withstand the pressure in emergency situations, like if a container is involved in an accident or the liquid starts swaying in the container back and forth. However, with their user-friendly design, three-handle containers are well-suited for static storage or for carrying cargos that don't demand the same level of structural reinforcement.

Operational Efficiency and Industry Preferences

In the shipping and logistics industry, the choice between three-handle and four-handle containers often depends on transport vs storage requirements, handling needs, and operational efficiency considerations. Generally, three-handle containers are not used in a shipping lines/logistics providers’ fleet due to quicker wear and tear, limited cargo range, and a shorter lifespan.

Stay tuned for more insights into the fascinating world of shipping containers or visit VS&B Containers. #ContainerInsights #Logistics #ShippingContainers

VS&B Containers, headquartered in Chennai, began operations in 1996. The company offers a wide variety of containers, both newly built and used, and custom-built units that can be directly shipped from our manufacturing facilities to your preferred destinations across the world. We also operate a leased fleet of over 30,000 containers for both international leasing and domestic leasing (within India). If you have container requirements, do drop us an email at enquiry@vsnb.com and a member of our team will reach out to assist you.

Furthermore, iInterchange Systems (a VS&B group company) provides state-of-the-art software solutions tailored specifically to meet the needs of container shipping and logistics enterprises. Please visit www.iinterchange.com for more details.

- Log in to post comments